Page 33 - Univac Catalog_E_Book

P. 33

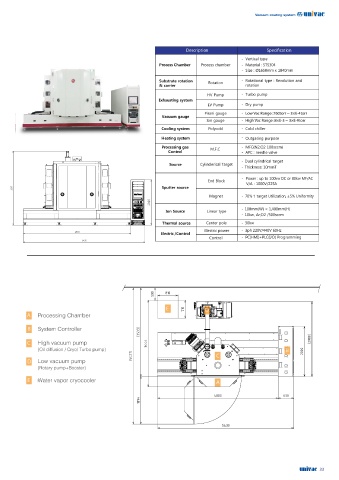

AR/AF SPUTTERING SYSTEM Description Speci cation

- Vertical type

Process Chamber Process chamber - Material : STS304

- Size : Ø1650mm x 1840mm

Substrate rotation Rotation - Rotational type : Revolution and

& carrier rotation

HV Pump - Turbo pump

Exhausting system

LV Pump - Dry pump

Pirani gauge - Low Vac Range :760torr ~ 3×E-4torr

Vacuum gauge

Ion gauge - High Vac Range :8×E-3 ~ 3×E-9torr

Cooling system Polycold - Cold chiller

Heating system - Outgasing purpose

Processing gas M.F.C - MFC(N2,O2 100sccm)

Control - APC : needle valve

- Dual cylindrical target

Source Cylinderical Target

- Thickness: 10mmT

- Power : up to 100kw DC or 80kw MF/AC

End Block

V/A : 1000V/225A

Sputter source

Magnet - 70%↑ target Utilization, ±5% Uniformity

EnerPulse 10

- 100mm(W) × 1,400mm(H)

Ion Source Linear type

- 10kw, Ar,O2 /500sccm

BENEFITS Thermal source Center pole - 30kw

Electric power - 3ph 220V/440V 60Hz

Electric /Control

- AR/AF coating by sputtering Description Speci cation Control - PC(HMI)+PLC(I/O) Programming

Substrate cleaning by LIS - Vertical type

- High density / Uniformity Process Chamber Process chamber - Material : STS304

High deposition rate - Size : Ø1650mm x 1840mm

Process stability Substrate rotation Rotation - Rotational type : Revolution and

Easy replacement target & carrier rotation

HV Pump - Turbo pump

Exhausting system

LV Pump - Dry pump

Pirani gauge - Low Vac Range :760torr ~ 3×E-4torr

Vacuum gauge E D

Ion gauge - High Vac Range :8×E-3 ~ 3×E-9torr A Processing Chamber

Cooling system Polycold - Cold chiller

B System Controller

Heating system - Outgasing purpose

Processing gas M.F.C - MFC(N2,O2 100sccm) C High vacuum pump

Control - APC : needle valve

(Oil diffusion / Cryo/ Turbo pump) B

- Dual cylindrical target C

Source Cylinderical Target D Low vacuum pump

- Thickness: 10mmT

(Rotary pump+Booster)

- Power : up to 100kw DC or 80kw MF/AC

End Block

V/A : 1000V/225A E Water vapor cryocooler A

Sputter source

Plasma Magnet - 70%↑ target Utilization, ±5% Uniformity

Ti

Ion Source Linear type - 100mm(W) × 1,400mm(H)

Ti - 10kw, Ar,O2 /500sccm

Thermal source Center pole - 30kw

Electric power - 3ph 220V/440V 60Hz

Electric /Control

Control - PC(HMI)+PLC(I/O) Programming

Chamber wall

33